As the pioneers of this instrument, James Heal celebrates over 80 years of the Martindale, and also a very special latest addition to the range.

Read on to learn the fascinating history behind its invention.

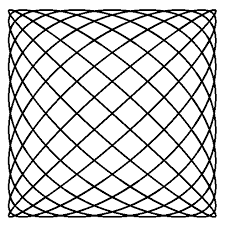

straight line, from which progressively widening ellipses develop in a diagonally opposite direction before the pattern is repeated.

straight line, from which progressively widening ellipses develop in a diagonally opposite direction before the pattern is repeated.▪️ 1950s

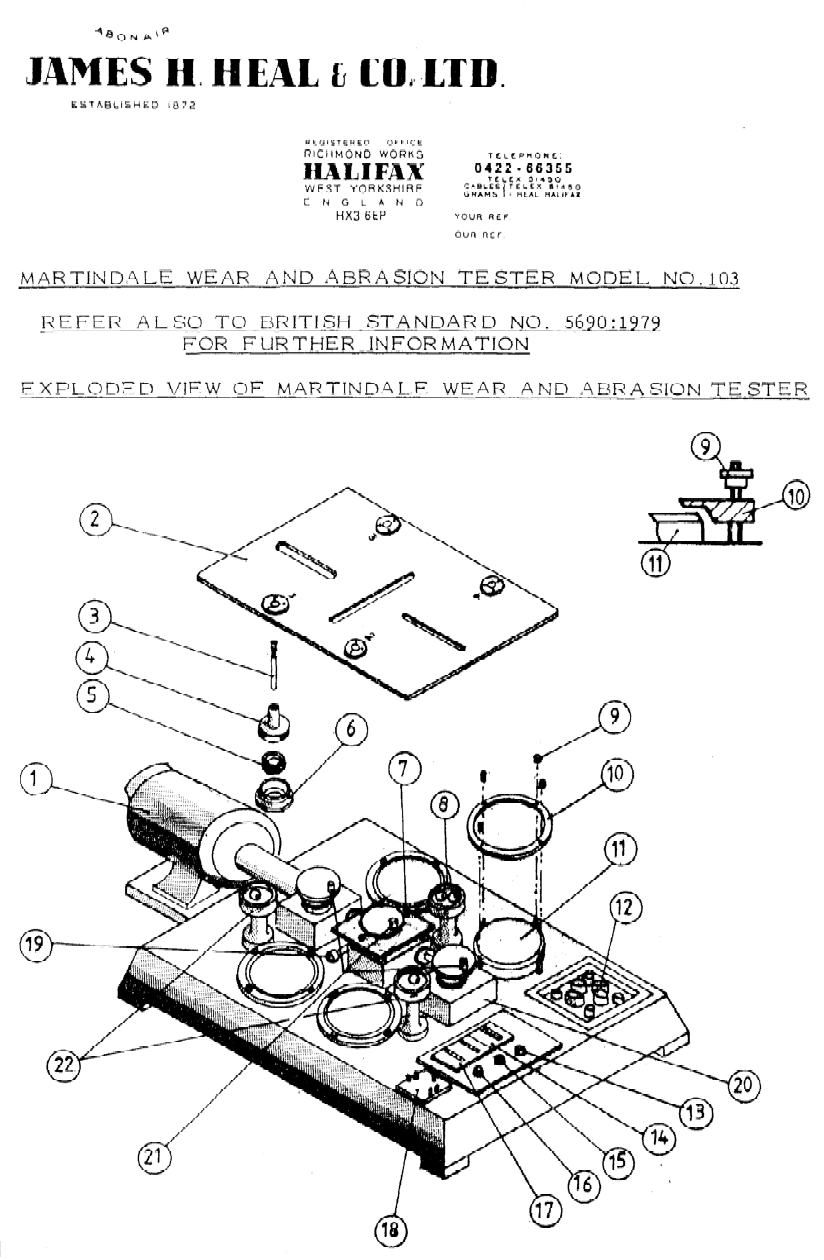

James Heal began to develop its own Martindale, it is believed with the collaboration of Dr. Martindale. This version had an added feature of a pre-determined electric counter, which stopped the machine automatically when a pre-set number of rubs was reached. Click here to see an original sales leaflet of Model No. 103.

▪️ 1960s and 1970s

The Martindale 103 model continues to evolve with regular improvements in design and functionality over two decades.

▪️ 1980s

At the 1987 ITMA Exhibition in Paris, James Heal was one of only a small number of companies exhibiting the Martindale.

▪️ 1990sThe early 1990s saw a redesign of the instrument introducing the innovative 6-station Martindale 403, launched in 1992 with quick locking clamp rings and a hinged top plate.

Launched at the 1999 ITMA exhibition in Paris, the 406 set a new benchmark in design and functionality with a clear LCD screen and auto restart function.

▪️ 2003

Our next model, Martindale 864, offered more choices with 4, 6 or 8 stations and an ergonomic top plate design for easy access and optional variable speeds.

▪️ 2010

This was the year that James Heal took its brand to a whole new level. Working with the Design Council, James Heal rebranded as a company whilst significantly changing the look of the instrument range to sleek black and stainless steel, with distinctive blue LED lighting. Inspired by over 60 years of accumulated knowledge and expertise, the 900 Series was focused on our core values of innovation, quality and precision.

▪️ 2014

The 1300 Series was launched in 2014 and introduced a hinged top plate to allow easy access to every station from the front to reduce the time to load and unload.

▪️ 2025

The Martindale Motion is released in Spring, heralding a new era of dynamic abrasion and pilling testing, designed for the labs of the future. Martindale Motion has independent lifting test heads and a suite of new easy access, and user-friendly features.

Take a look at our timeline to see how the Martindale has evolved over time through the images and documents from our archive, including the original test method published in 1942.

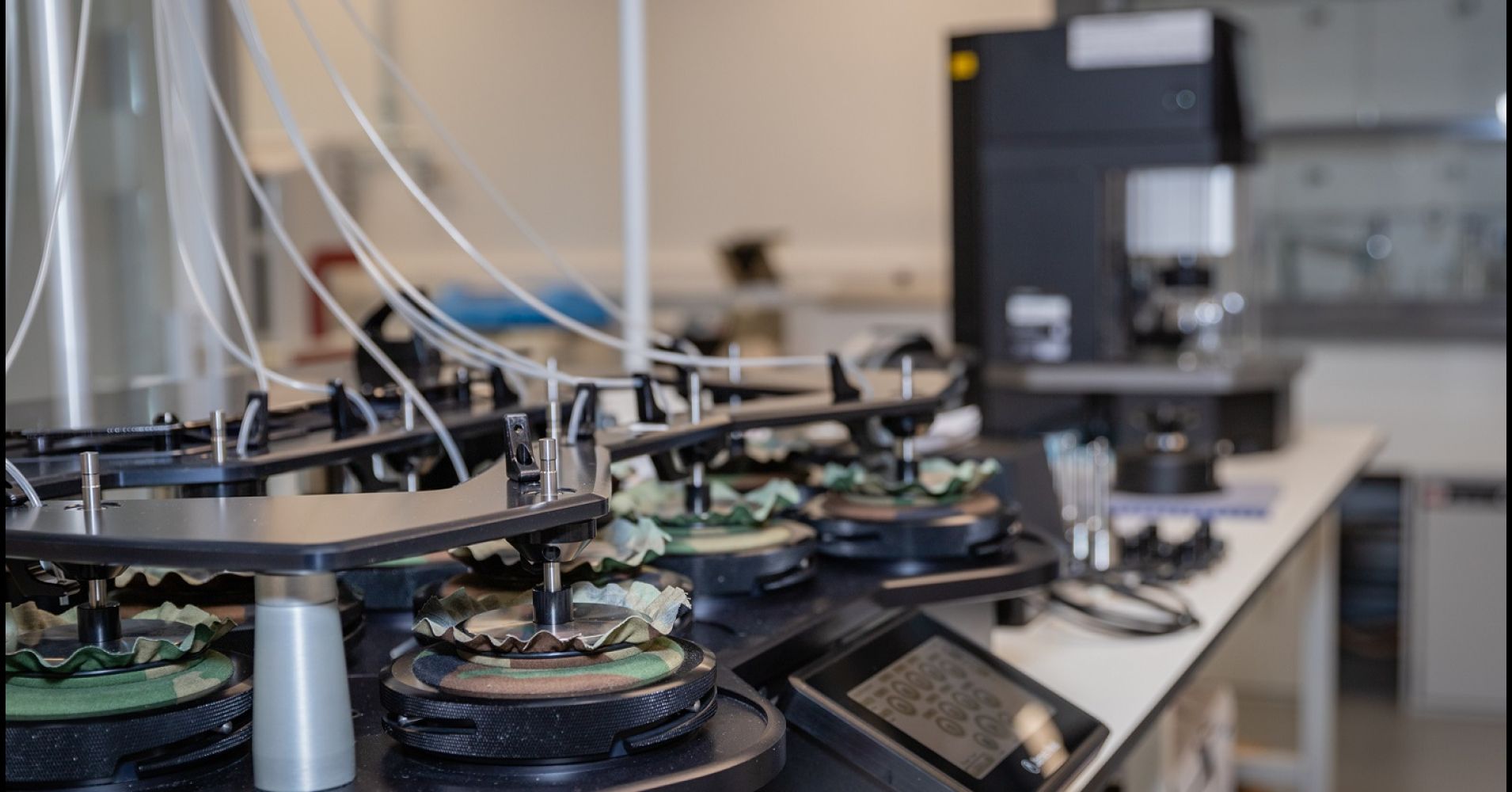

It's Spring 2025, and the Martindale Motion has been launched. With individual lifting test heads, designed to increase the flexibility and productivity of routine testing, the Martindale Motion marks a new era of abrasion and pilling testing.

Updates and additions to the integrated TestWise software offer new features, such as automatic homing for pin change, lifting presets, and test switch assist.

Learn about the features and benefits of the new instrument on our Martindale web page where you can also download the latest brochures, giving details of the full range include 2-, 5- and 9-station models, as well as AquAbrasion and Martindale Motion.

Testing applications on our Martindale range include:

There are many Standards relating to these tests, which can also be found on our website, together with Martindale Test Materials.

Responding to shifts in consumer expectations and trends towards athleisure and performance wear, James Heal developed AquAbrasion - a wet abrasion tester. The first of its kind, AquAbrasion was launched as part of the Performance Range at ITMA Barcelona in 2019.

Based on the traditional Martindale instrument, the AquAbrasion is an accurate and repeatable way of conducting wet abrasion testing, which has proven to be a crucial step in establishing the durability of outdoor and performance wear in relation to real life situations.

“Today, there are many more companies making the Martindale device,” explains Neil. “However, James Heal has built on its pedigree and continues to innovate, developing a range of Martindale abrasion and pilling testers with the adaptability to test a wide range of applications from textiles, to wood and most recently, wet abrasion testing. The AquAbrasion can be used to test the effects of rainwater, perspiration or chlorinated water on textiles, leather and other materials, as well as liquids such as sunscreen or hand sanitiser.

“Since our involvement in the creation of the early models of the Martindale, we have continued to listen to what users and customers need; responding to consumer trends and market demand to develop and improve our flagship instrument. We have sold thousands of Martindale testers over the decades, underpinning our position as a leading supplier and innovator in precision testing instruments. Our Martindale series continues to evolve, keeping our product innovation team very busy. Look out for exciting announcements on further new developments to this classic instrument!” concludes Neil.

The Performance Range is designed specifically for testing performance and technical textiles. Built for a range applications instruments include an air permeability tester, dry rate tester, hydrostatic head tester, water permeability tester and moisture wicking tester. also known as a moisture management tester. Learn more about the new performance testing range, here: performance.jamesheal.com